Valvunaval is created in 1965 by engineers coming from Euskalduna Shipyards (Bilbao), interested in the creation of an Industrial Hub in Burgos*.

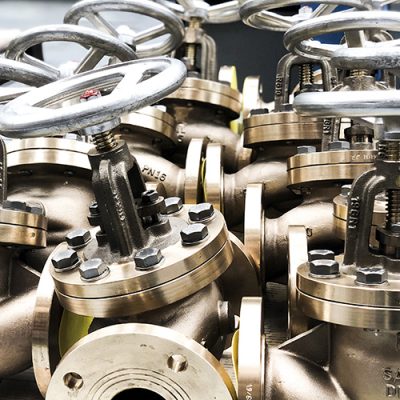

During his early years Saval specializes in special valves (oil and fuel oil) and are very involved in the trans-Siberian railway project.

As a remarkable fact, Saval was awarded a diploma by the Chamber of Commerce and Industry in September 1971, recognizing its development of export activities.

In 1973 the shareholding is acquired by Pegler Group, a group dedicated to naval and petrochemical valves.

During the recession of the late '70s, the group decided to close several factories including the one in Burgos.

In that moment the employees decide to acquire the shareholding, becoming actions Valnaval Cooperative Society, comprised of 57 members.

The company will be a cooperative until 1994.

That year, ten old members decided to found Saval de Valvulas, maintaining its share in the domestic and international markets as leading manufacturers for clients such as Armon Shipyards, Gondan Shipyards, and later on Navantia (2004 Shock Test Homologation 1000).

During these years Saval achieved considerable exports to the German market (400,000 € / year approx.) for Siemens, ABB, etc.

This niche is finished when the customers start to import valves from Asian producers valves at low cost.

In 2012, Saval de Valvulas S.A. becomes part of Fernandez Jove Group S.A.

In 2015 Saval valves moves to a new factory located in Torrelavega, Spain