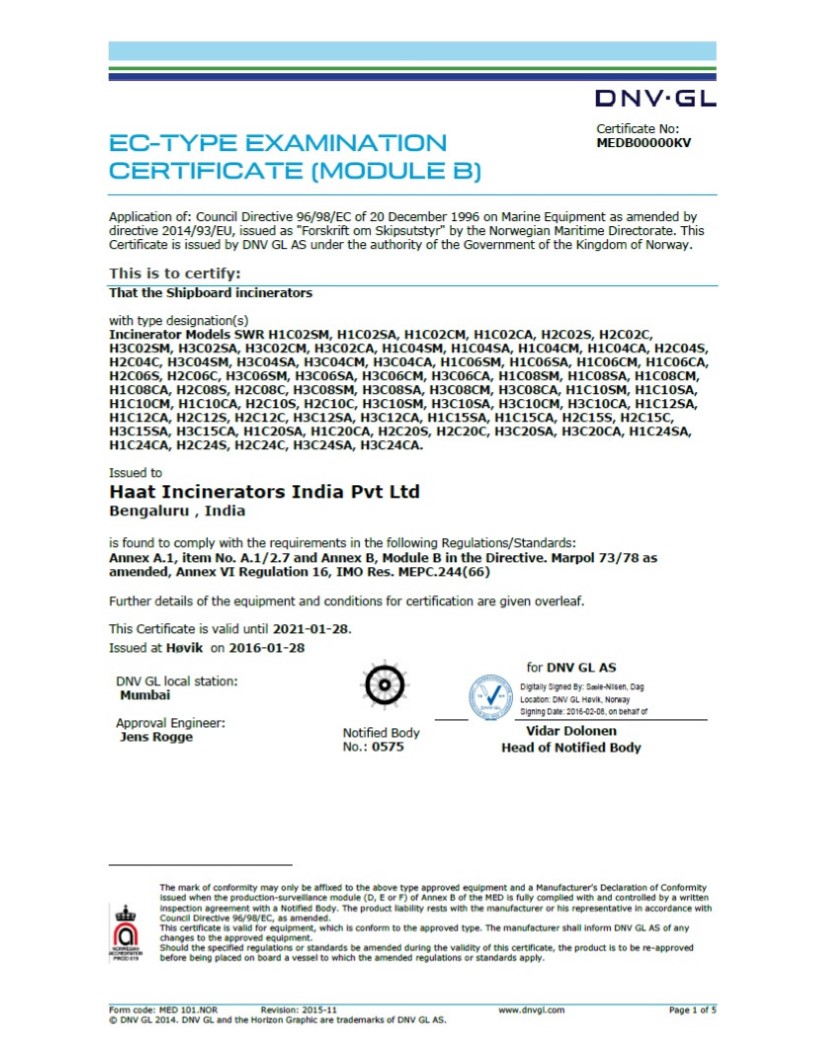

HAAT Incinerators India Pvt Ltd is an engineering company from the Garden City of India, Bangalore. HAAT was founded in 1999 and works on environmental engineering technologies all over the world with special emphasis on incineration. HAAT has successfully supplied and commissioned many incineration plants, air pollution and flue gas treatment equipment, waste size reduction shredding machinery, thermal oxidizers and trash destructors in practically every sector.

HAAT understands the rigorous requirements of clients when it comes to documentation, drawings, quality assurance, fabrication and installation and service support. HAAT makes modular products that involve maximizing work at their shop to minimize site work. Certain skid mounted models require practically no work at site except for provision of utilities.

With many years of experience in almost every industrial sector, HAAT is able to provide you both custom and standard services and solutions. Equipment can comply with the best of regulations as the primary emphasis of HAAT's products is on critical safety and environmental issues.

HAAT is certified to ISO 9001:2008, 14001:2004 and 18001:2007.

MOTEC is an official supplier of HAAT incinerators.

As an incinerator manufacturer, HAAT has been in the forefront of waste management activities for nearly two decades.

HAAT has both standard and customized models in its range for use in different and varying applications. Standard or tailor-made incinerators are those where the type of waste, its contents and calorific value are all well known. Whereas certain applications like industrial hazardous waste (which has a wide spectrum of varieties, contents, characteristics and calorific values) require customized designs. Thermal oxidisers and furnaces for recovery of catalysts are another set of examples where the entire design is governed by the nature, varying volume and characteristics of the different gaseous wastes. The incinerator manufacturer, therefore, has to think out of the box, in as much as he is not doing a simple fabrication job but in reality making the shoe fit the foot and not the other way round.

Incineration is not about just burning garbage. There is any number of applications, if it comes to it. These include:

• Industrial hazardous waste

• Municipal solid waste

• Biomedical waste

• Sanitary napkin waste

• Animal waste

• Pharma waste

• Nuclear waste

• R & D waste

• Paper and packaging waste

• Remote camp waste

• Food & confectionary waste

• Confidential documents and drawings waste

• Used currency notes waste

• Paint sludge waste

• Recovery of precious metal

• Catalyst recovery

• Condensate oil waste

By no means is the above list complete as more and more new wastes are being exposed!

The industries generating these wastes are:

• Off shore and On shore oil & gas drilling sites

• Paint manufacturers

• Automobile Manufactures

• Hospitals and nursing homes

• Municipalities and Corporations

• Fertilizer manufacturers

• Packaging industry

• Pharma industry

• Nuclear establishments

• Power stations powered by diesel generators

• Remote camps (e.g. Antarctica)

• Food product manufacturers

• Defence establishments

• Poultry industry

• Abattoirs

• Zoological parks

• Hostels and canteens

• Textile industry

• Residential areas and apartments

• Hotels and Restaurants

• Wedding halls

• Malls

This list also could be endless – stretching to all possible areas of human interaction.